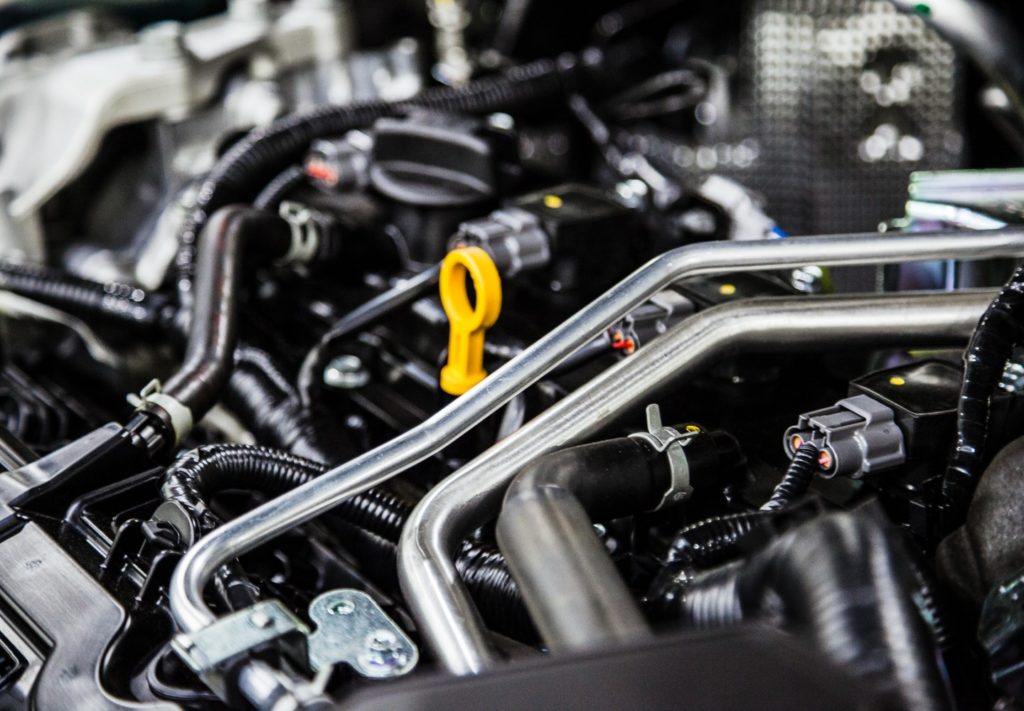

Cold Rolled Steel Tube

Extra processing makes low carbon, cold rolled steel tube strong and smooth.

Strong and Smooth

We mill Phillips Cold Rolled Steel Tube from steel that undergoes less heat and more pressure. Steel manufacturing takes place below recrystallization at room temperature.

A cold mill outfitted with specially roughened rollers provides additional processing, giving the steel a uniform, matte finish. Each cold rolled steel tube comes smooth to the touch and readily paintable using essentially any paint system.

Available in a wide range of thicknesses and chemistries, cold rolled steel tube is best suited for parts with a fine finish fabricated in a variety of ways: Bending, expansion, penciling, flattening and extreme deep drawing.

-

Outside Diameter Capabilities

.3125” (7.938mm) – 5.000” (127mm)

-

Gauge Capabilities

.028" (.711mm) – 157 (4.0mm) Length Capabilities

-

Length Capabilities

1.25" - 240.00"

-

Shape Capabilities

D-shape, Double-D, Round, Square, Rectangle, Oval, and Specialty Shapes

-

End Conditions

Haven Cut, Mill Cut, Brushed, Brushed Deburred, Drop, End facing, and Chamfering

-

Finishing

ID/OD scarfing to remove extruded weld bead