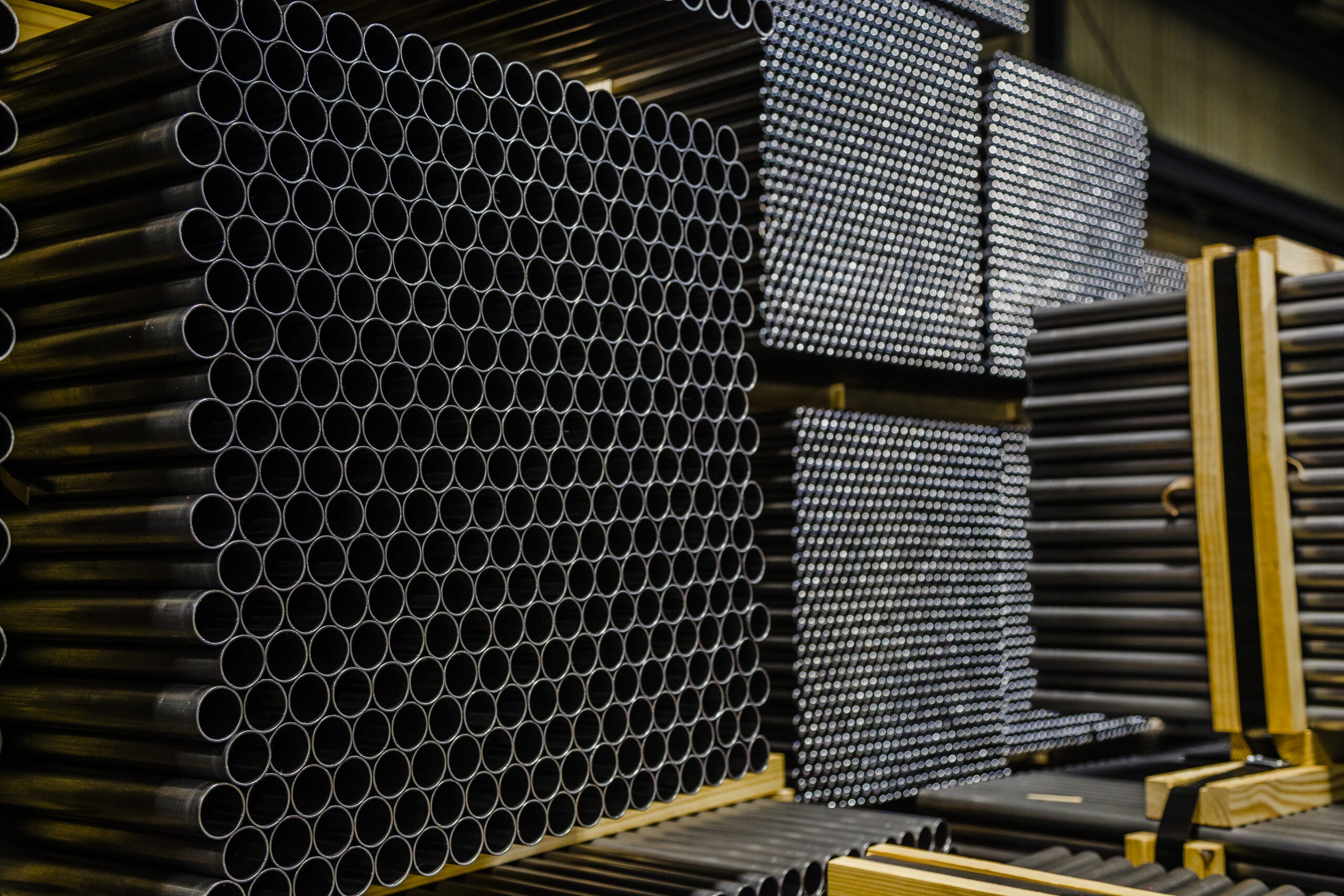

When it comes to steel tubing, not all tubes are created equal. Coated steel tubes, in particular, offer unique properties that make them ideal for various demanding applications. Understanding the different types of coated steel tubes and their specific uses can help you select the best material for your project.

Aluminized Steel Tube

Aluminized steel tubes

are crafted through a continuous hot-dip process that coats the steel with an aluminum-silicon alloy. This combination results in a tube with superior corrosion resistance and heat protection. The aluminum layer shields the steel core from harsh environmental factors, making it an excellent choice for applications exposed to high temperatures. Common uses include automotive exhaust systems, HVAC equipment, and various household appliances like water heaters and furnaces. The aluminized coating also provides effective resistance to salt exposure, adding to its versatility.

Galvanized Steel Tube

Galvanized steel tubes are an umbrella category that includes several types of zinc-coated steel tubes, each offering specific advantages for various applications. The galvanizing process involves applying a zinc coating to protect the steel from corrosion, making these tubes suitable for use in some of the most corrosive environments.

- Conventional Galvanized Steel Tube: This type of tube undergoes a continuous hot-dip or electric zinc coating process, providing robust corrosion resistance. It is commonly used in automotive manufacturing, construction, and HVAC systems.

- Galvalume Steel Tube: Coated with a zinc-aluminum alloy, Galvalume tubes offer excellent corrosion and heat resistance. They are ideal for long-term resistance to atmospheric corrosion, making them a great choice for automotive applications.

- Galvannealed Steel Tube: The zinc coating process, in conjunction with heat treatment of the steel, creates a zinc-iron alloy. The result is a tube with enhanced paint adhesion and excellent corrosion protection, making it popular in automotive manufacturing and general manufacturing.

- Electrogalvanized Steel Tube: In this process, a zinc coating is applied through electroplating, which offers strong corrosion resistance and a smooth surface ideal for painting or powder coating. These tubes are often used in auto bodies, appliances, and small parts.

Each of these galvanized steel tubes is designed to provide robust protection against corrosion while offering specific properties that make them suitable for various industrial applications.

Zinc Nickel Steel Tube

Zinc-nickel steel tubes represent the pinnacle of corrosion protection, particularly in the most demanding environments. Coated with a zinc-nickel alloy, these tubes offer exceptional resistance to corrosion, even when exposed to salt, sand, and various fuels and fluids. They are easily powder-coated, making them ideal for automotive parts, especially in fuel systems for both on-road and off-road vehicles. The high-performance coating ensures long-lasting durability, making zinc-nickel tubes a top choice for critical applications where reliability is non-negotiable.

Choosing the Right Coated Steel Tube

Selecting the right type of coated steel tube is crucial for ensuring the longevity and performance of your project. Whether you need the heat resistance of aluminized steel, the robust corrosion protection of galvanized, galvalume, or galvannealed steel, or the high-performance capabilities of zinc-nickel, each type offers unique benefits tailored to specific applications.

At Phillips Tube Group, we prioritize quality and dependability, delivering premium products that meet the rigorous demands of various industries. By understanding the specific benefits and uses of each type of coated steel tube, you can make an informed decision that ensures your project’s success. Don’t compromise on quality—choose the best, choose Phillips Tube Group. If you’re ready to learn more about which coated steel tube is ideal for your next project, contact us today to explore our extensive product offerings.